THE CONSTRUCTIONIST.

AUG

30

READY-MIX CONCRETE: HOW IT'S MADE

Since 1983, Toronto Redi-Mix has been producing ready-mix concrete and supplying projects throughout the GTA. Let’s discover how concrete, a primary building material throughout the world, is made!Ready-mix concrete is a customized concrete mixture, prepared according to specific project requirements. This product is made at our concrete plants in Concord, Brampton and Etobicoke to be delivered to construction sites, perfectly batched and ready to use.

Ready-mix concrete is composed of cement, aggregates (sand and gravel or crushed stone), water, and additives. Each component is weighed to ensure accurate proportions are added into the mix. The component ratios are determined by the customer’s mix design and the end use of the product. When in doubt, always consult the Ontario Building Code (OBC) for minimum requirements.

Here is a behind-the-scenes look at the magic of ready-mix production:

STEP 1

The aggregates make their way from our yard up a 200+ ft. belt to our plant. Depending on the mix specifications, aggregates may include a combination of concrete stone and concrete sand.

STEP 2

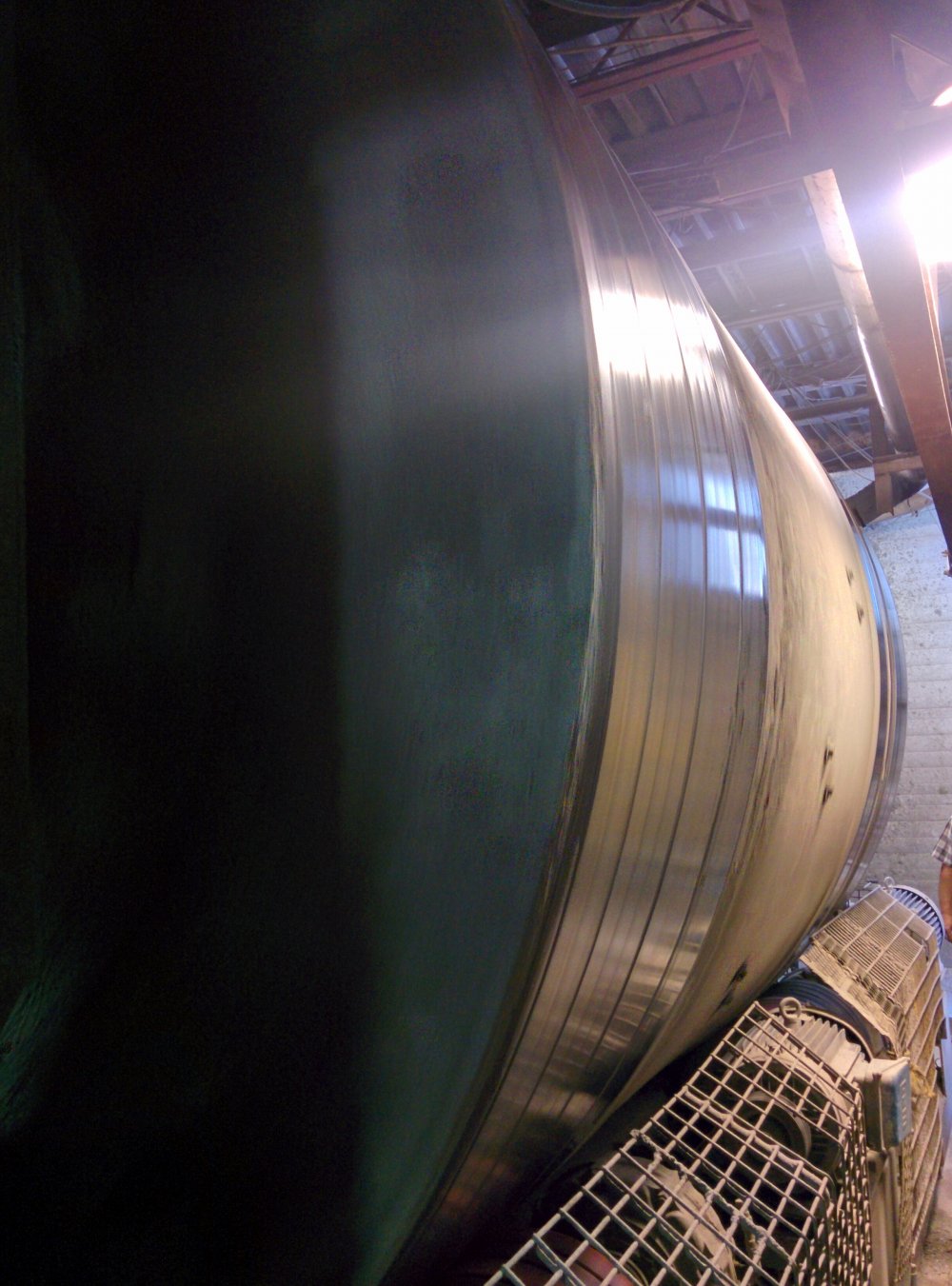

After travelling up the belt, aggregates fill the designated bins inside the tower where material is kept clean and dry. This allows for year-round ready-mix production, avoiding weather-related issues like wet or frozen aggregate material.

STEP 3

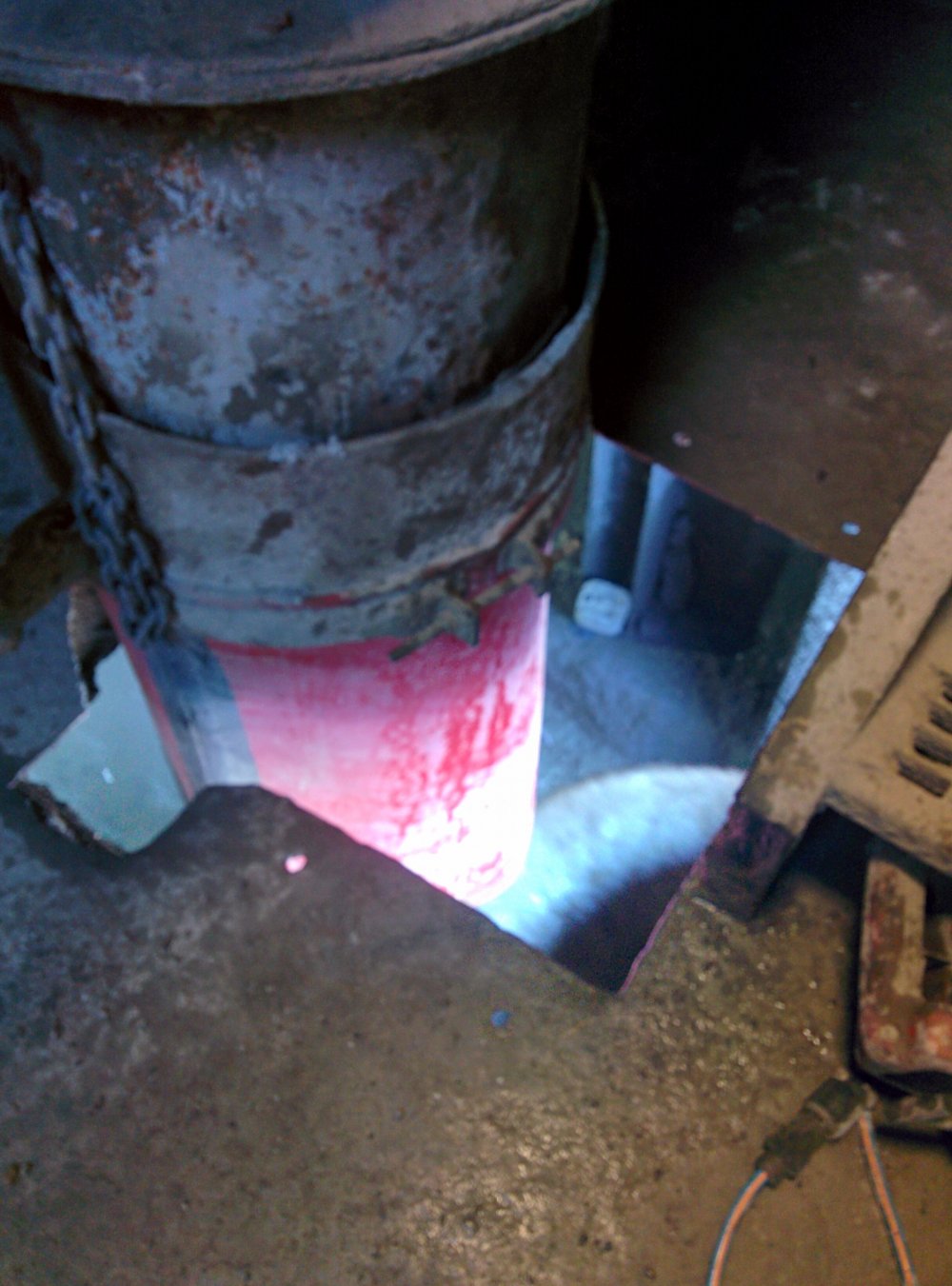

Our Batcher dispenses aggregates from the bins, plus cement powder, water, and necessary additives, into the drum for spot-on mix designs. Additives, also called admixtures, react with the concrete mix and alter its properties. For example, accelerator additives speed up the setting time of concrete, whereas retarder additives slow down this process. Depending on the customer preferences and applications, different additives may be added into the mix.

STEP 4

The drum spins around to mix the batch evenly. The result is a custom-made mixture with precisely calculated ratio of ingredients – intended for its specific use.

STEP 5

When the drum stops, the driver positions the truck underneath the chute where he ‘loads and goes’! Because ready-mix concrete is perishable, the driver heads out right away to ensure the mix is fresh and ready to use. Ready-mix concrete saves time and labour costs; ensures consistent quality; and offers enhanced durability of structure.

For more information about our ready-mix concrete, call 416.798.7060 or visit TorontoRedi-Mix.com.

Looking for concrete for your residential project? Build your order online today at torontoredi-mix.com/order-concrete.

FIND A LOCATION NEAR YOU

BY POSTAL CODE

KMBY CITY